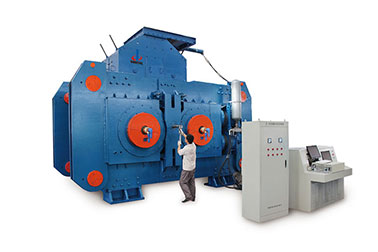

GM Series High Press Grinding Roller(HPGR)

Share

Designed by SATT, national key technology R&D project, invention patent, international advanced technology, well solution to fine crushing of various type of mineral ores.

Patent No.: ZL 2009 1 0116979.8

Brief Introduction of GM Series High Press Grinding Roller(HPGR)

The HPGR system we offered is well designed an precisely assembled for smooth operation and a long service life. It provides advantageous crushing effect and system throughput which offer a 30 percent leap on capacity and a 20 percent decline on energy consumption than traditional process due to its superior roller surface design in both structure and material.

Application of GM Series High Press Grinding Roller(HPGR)

HPGR is a new type of equipment applied advanced crushing theory to adapt the characteristics of metal ore. It is widely used in the process of crushing of pellet feed and various type of mines, especially in metal mines including iron, manganese, copper, gold and diamonds.

Advantage

HPRG will significantly improve the capacity of the crushing system, as well as reduce electric energy and steel ball consumption of ball mill.

With features of high wear resistant roller surface, great crushing ratio, higher availability, investment and cost saving and flexible configuration, the HPGR is capable to process various kinds of ore 50-1800 t/h.

It has various advantages including solid structure, wearable roller surface, high efficiency and energy-saving.

Test and Customized Service

With full equipped test devices, we provide reliable data to determine suitable type by a series of test including crushing test, grindability test, bond grinding work index test and tailing discharging test, and then recommend the most suitable type.

Technical Parameter of High Pressure Grinding Roller(HPGR)

| Series | Specification | Roller Diameter(mm) | Roller Width(mm) | Feed Size(mm) | Throughput(T/H) |

| 10 Series | GM100/30 | 1000 | 300 | le;40 | 50-100 |

| GM100/40 | 1000 | 400 | le;40 | 80-140 | |

| 12 Series | GM120/40 | 1200 | 400 | le;50 | 100-200 |

| GM120/80 | 1200 | 800 | le;50 | 150-400 | |

| 15 Series | GM150/50 | 1500 | 500 | le;60 | 150-350 |

| GM150/80 | 1500 | 800 | le;60 | 350-500 | |

| GM150/120 | 1500 | 1200 | le;60 | 400-800 | |

| 17 Series | GM170/60 | 1700 | 600 | le;65 | 250-550 |

| GM170/120 | 1700 | 1200 | le;65 | 500-1100 | |

| GM170/150 | 1700 | 1500 | le;65 | 700-1400 | |

| 20 Series | GM200/80 | 2000 | 800 | le;70 | 400-850 |

| GM200/120 | 2000 | 1200 | le;70 | 600-1300 | |

| GM200/160 | 2000 | 1500 | le;70 | 900-2000 |

Remarks: Above types and parameters are for reference only. We offer customized service to determine and fulfill specific requirements through a series tests and specialized ddesign in addition to standard works.