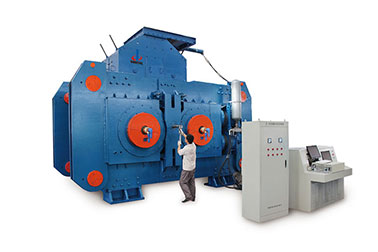

Permanent wet drummagnetic separator(CT series)

Patent No.: ZL200420025418.X ZL200820042298.2 ZL201120315270.3

Share

Since 1969, beneficiation solution supplier, the team lead by 6 professional talented experts enjoying special allowance of the State Council.

Patent No.: ZL200420025418.X ZL200820042298.2 ZL201120315270.3

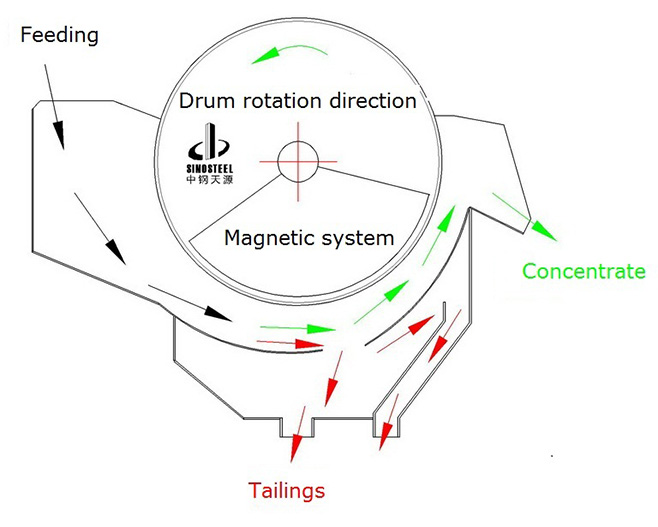

Name: Concurrent Type

Operation principle of Permanent wet drummagnetic separator

The flow direction of feed ore slurry is consistent with the drum rotation direction, with co-rotation of drum, the magnetic minerals are absorbed on the drum surface when the slurry flow through the drum separation area, and discharged on the concentrate outlet tank located on the opposite side of magnets system. Meanwhile, the non-magnetic and weakly magnetic minerals are discharged on the tailing outlet tank.

Application o

It is used to separate high magnetic minerals with size between 6 and 0 mm on the stage of roughing and cleaner process.

Advantage

High capacity and high concentrate grade.

Principle diagram for concurrent type magnetic separator

Name: Complete Countercurrent type

Operation principle

The Flow direction of feed ore slurry is opposite with the drum rotation direction, with counter rotating of drum, the magnetic minerals are absorbed on the drum surface when the slurry flow through the drum separation area, and discharged on the concentrate outlet tank located on the same side of feed box. Meanwhile, the non-magnetic and weakly magnetic minerals are discharged on the tailing outlet tank located on the opposite side of magnets system.

Application of Permanent wet drummagnetic separator

It is used on separate high magnetic minerals with size between 6 and 0 mm on the stage of roughing and scavenging process, and recover the heavy medium in the coal washing.

Advantage

It could discard low grade tailing in a large quantity, reduce the load of secondary grinding, improve metal recovery and save the power and washer consumption.

Principle diagram for Semi- Countercurrent type magnetic separator

Name: Semi- Countercurrent type

Operation principle

The ore slurry feed into the separation are from the middle of the tank. The direction of feed is nearly the same with attractive force direction of magnetic field. With the co-rotating of drum, the magnetic minerals are absorbed on the drum surface and discharged on the concentrate outlet tank. Meanwhile, the non-magnetic and weakly magnetic minerals are discharged after scavenging area on the tailing outlet tank by the opposite rotary direction of drum. The horizontal plane of slurry in the tank keeps steady.

Advantage

It could improve both concentrate grade and metal recovery.

Principle diagram for Semi- Countercurrent type magnetic separator

Name: Thickener Separator

Application

It is used to improve the density of magnetic minerals.

Advantage

High recovery for strong magnetic minerals, High capacity and outstanding thickener effects.

It could replace the dewatering tank and thickener tank with large occupation area in the process of thickening of strong magnetic minerals.

It could improve the concentrate density by the blades discharge.

It could improve the feed density before filter proves, and improve the efficiency of filtering and the water content index of concentrate.

It could improve the density of coarse concentrate when used before the third-stage grinding.

CT series wet type drum permanent magnetic separator Technical Parameters